Introduction

What is Product LifeCycle Management?

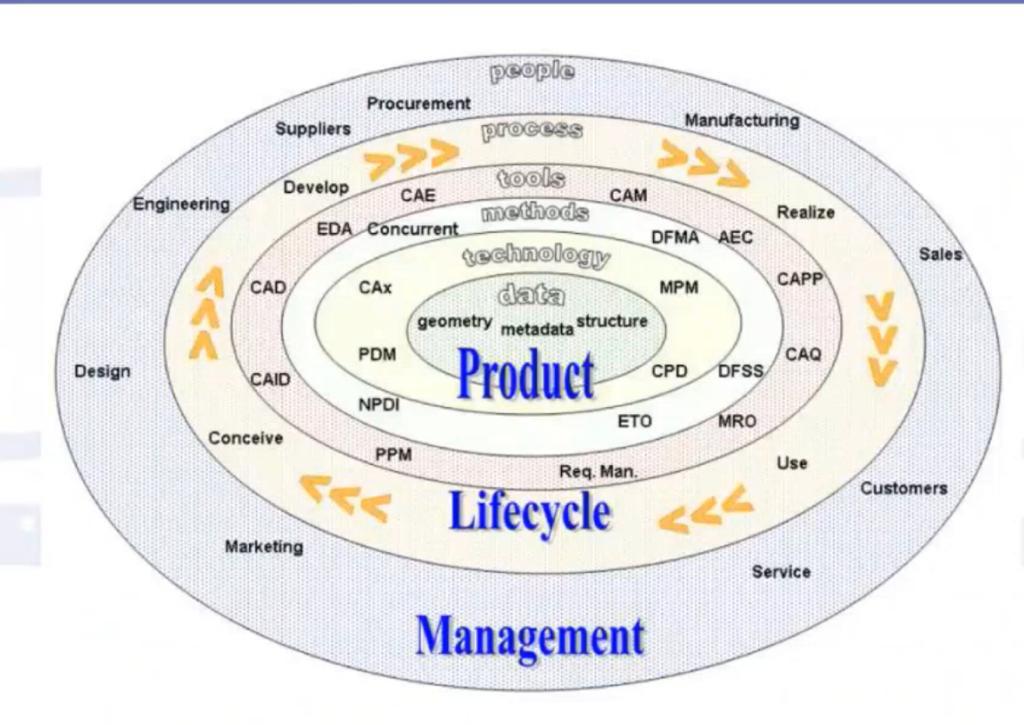

It is a solution that manages the complete journey of a product from Initial Ideation, Development, Service, and Disposal. In a simple term, it manages everything involved with a product from cradle to grave. It involves into several phases from Design – > Manufacturing – > Distributing ->Consumer ->End of Life

Figure 1: – Product Life Management

Benefit of PLM – Product Lifecycle Management

There are many benefits that a Product Lifecycle Management provides. some of the few Manin benefits are the following

- Manages the complete journey of product

- Manages information of a product

- Manages the process of a product

- Avoid repeating to create efficiency

- And many more

Product Lifecycle Management

Product Lifecycle Management is a key to facilitate different management activity that a product has to go through from initial step until the end that the product is ready for consumer. The Four major sector that PLM involves are following

- Project Mangagement

- Quality Management

- Health and safety

- Asset Management

PLM – Product Lifecycle Management

Product Lifecycle Management has several layer to address the different inputs that a PLM is using to conduct the purpose of the methodology. The following are the elements that a product lifecycle management has

- People : – Refers the team members working in realizing the project

- Process : – Refers the standards and flow in the phase product development

- Tools : – It plays a vital role right from the stage of conceiving of the idea to designing the product with aesthetic appeal to developing the product level drawings and lastly to the validation/analysis stage.

- Methods

- Technology

- Data : Refers File or Meta Data that could be used to construct the code of a product

Figure 2: – Product Life Management Elements

PLM Series of Modules

There are several module that PLM composed to contribute and collaborate in the development of a product.

- Project Data Management– refers technical document of a product

- Product Structure Management refers configuration of a product – BOM

- Configuration Management refers the management of variant in production

- Change Management – Refers the management of changes to a product

- Workflow Mangement

- Catalog Library

- Supply Chain Management

- CAD[Computer Aided Design] CAM[Computer Aided Management] CAE[Computer Aided Engineering]